Understanding the Role of an Optical Fibre Diameter Analyser in Optical Communications

Understanding the Role of an Optical Fibre Diameter Analyser in Optical Communications

Blog Article

Comprehending the Capability of an Optical Fibre Diameter Analyser in Modern Manufacturing

The optical Fibre Diameter analyser offers as a critical instrument in contemporary manufacturing, providing specific, non-contact measurements that are vital for keeping stringent market requirements. By leveraging sophisticated laser innovation, these analysers not just ensure minimal signal loss yet also boost the overall efficiency of optical fibres.

Significance of Optical Fibre Measurement

In modern production, the measurement of optical Fibre Diameter is vital for making sure the efficiency and reliability of Fibre optic systems. Accurate Diameter dimension straight affects optical performance, as variations can bring about boosted signal loss, minimized data transfer, and decreased overall effectiveness. The optical homes, consisting of light transmission and signal honesty, are extremely conscious the Fibre's Diameter, necessitating precise control throughout production.

Moreover, standardization in Fibre Diameter is important for compatibility and interoperability within varied telecommunications networks. As these networks broaden globally, maintaining uniformity in Fibre characteristics advertises smooth assimilation throughout different components and systems. In addition, sticking to industry requirements worrying Diameter tolerances is vital for suppliers to fulfill regulative needs and customer assumptions.

Buying advanced dimension modern technologies not just enhances manufacturing effectiveness however also supports quality assurance processes, allowing makers to determine problems early in manufacturing. This proactive technique reduces waste and ensures that the final items meet stringent efficiency standards. Consequently, the relevance of optical Fibre dimension can not be overstated, as it acts as a foundation for top notch, reputable Fibre optic systems, which are essential to modern-day communication facilities.

Just How Diameter Analysers Work

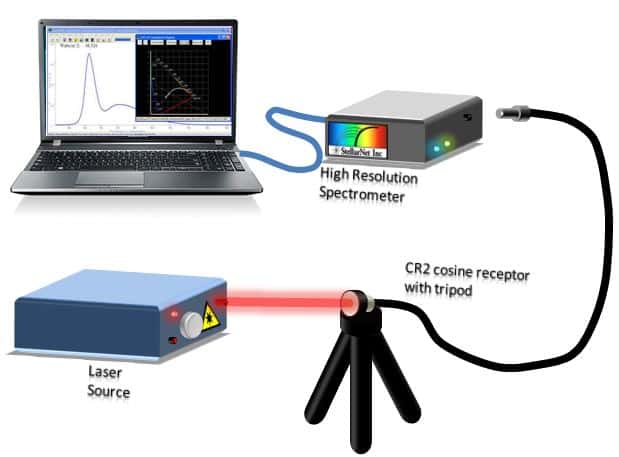

The core operation depends on the concept of light spreading and reflection. As the laser light beam strikes the Fibre, variations in Diameter cause modifications in the light's strength and wavelength (optical fibre diameter analyser). This information is processed in real-time using advanced formulas that convert the optical signals right into exact Diameter dimensions

In addition, many Diameter analysers are equipped with multiple dimension factors along the Fibre, allowing for a comprehensive analysis of Diameter uniformity. The implementation of such innovation dramatically improves high quality control in production, making certain that optical fibers are generated to exact requirements for ideal performance in their desired applications.

Secret Attributes to Think About

When choosing an optical Fibre Diameter analyser, numerous vital attributes require cautious consideration to make certain ideal performance and dependability. Measurement precision is extremely important; the analyser must give precise Diameter analyses, typically in micrometers, to fulfill stringent production requirements. In addition, a vast measurement variety enhances convenience, suiting various Fibre types and thicknesses.

One more critical attribute is the analyser's rate. Fast measurement abilities enable increased throughput, vital in high-volume production environments. Real-time information processing and responses capacities make it possible for immediate changes, enhancing top quality control.

Interface and software program compatibility are likewise considerable considerations. An user-friendly interface simplifies operation, while robust software assistance helps with information evaluation and assimilation with existing production systems. The capacity to export data in different layouts can boost reporting and compliance initiatives.

Moreover, toughness and maintenance requirements need to be assessed. An analyser created from high-grade materials will stand up to the rigours of a manufacturing environment, while convenience of upkeep makes certain longevity and minimizes downtime. Take into consideration the level of technological assistance and training given by the producer, as this can dramatically influence the effective use of the analyser in manufacturing setups.

Advantages in Production Performance

Enhancing production efficiency rests on the integration of sophisticated technologies, such as optical Fibre Diameter analysers. These instruments play a pivotal duty in making certain that optical fibres meet rigorous top quality criteria, which is vital for optimum performance in numerous applications - optical fibre diameter analyser. By offering real-time dimensions of Fibre Diameter, producers can quickly identify and rectify deviations from specified go to website tolerances, consequently lowering waste and reducing the danger of faulty products

Additionally, the very early detection of prospective concerns brings about lowered downtime and upkeep costs, consequently maximizing resource appropriation. Eventually, the performance obtains recognized with using optical Fibre Diameter analysers add to a more affordable production atmosphere, making certain that firms can deliver top notch products while preserving cost-effectiveness and responsiveness to market demands.

Applications Throughout Industries

The versatility of optical Fibre Diameter analysers prolongs beyond making effectiveness, finding applications across various sectors that count on optical Fibre modern technology. In telecommunications, these analysers are important for making certain the optimum efficiency of Fibre optic wires, directly impacting data transmission rates and network dependability. By precisely measuring Fibre sizes, drivers can minimize signal loss and enhance general communication high quality.

The medical market also profits dramatically from these devices, particularly in the growth of endoscopic tools and laser therapies. Exact Diameter measurements are essential for producing efficient optical fibers that are utilized in minimally invasive procedures, boosting client results with improved imaging and treatment capacities.

In aerospace, the analysers play a critical function in the manufacturing of lightweight, high-strength materials, where Fibre optics are incorporated into architectural components for tracking and diagnostics. Furthermore, the automobile market employs these tools to make certain the honesty of Fibre optic sensors that improve safety and security and performance features in automobiles.

Conclusion

In conclusion, the optical Fibre Diameter analyser is necessary for modern manufacturing, making certain exact measurements that maintain sector standards. The diverse applications across various markets underscore the analyser's value in advertising continuous renovation and data-driven decision-making within the production field.

In contemporary production, the dimension of optical Fibre Diameter is vital for ensuring the efficiency and reliability of Fibre optic systems. The relevance of optical Fibre measurement can not be overstated, as it offers as a foundation for high-grade, trusted Fibre optic systems, which are essential to contemporary communication framework.

Diameter analysers utilize innovative optical technologies reference to properly measure the Diameter of optical fibres.Furthermore, several Diameter analysers are equipped with numerous measurement points along the Fibre, permitting for a comprehensive evaluation of Diameter uniformity.The versatility of optical Fibre Diameter analysers prolongs past producing efficiency, discovering applications across various industries that Related Site depend on optical Fibre technology.

Report this page